The Use-Cases of CyberFactory#1

The key problem addressed by CyberFactory#1 is the need to conciliate the optimization of the supply and manufacturing chain of the Factory of the Future (analyzed by means of Use-Cases) with the need for security, safety and resilience against cyber and cyber-physical threats (analyzed by means of Misuse-Cases).

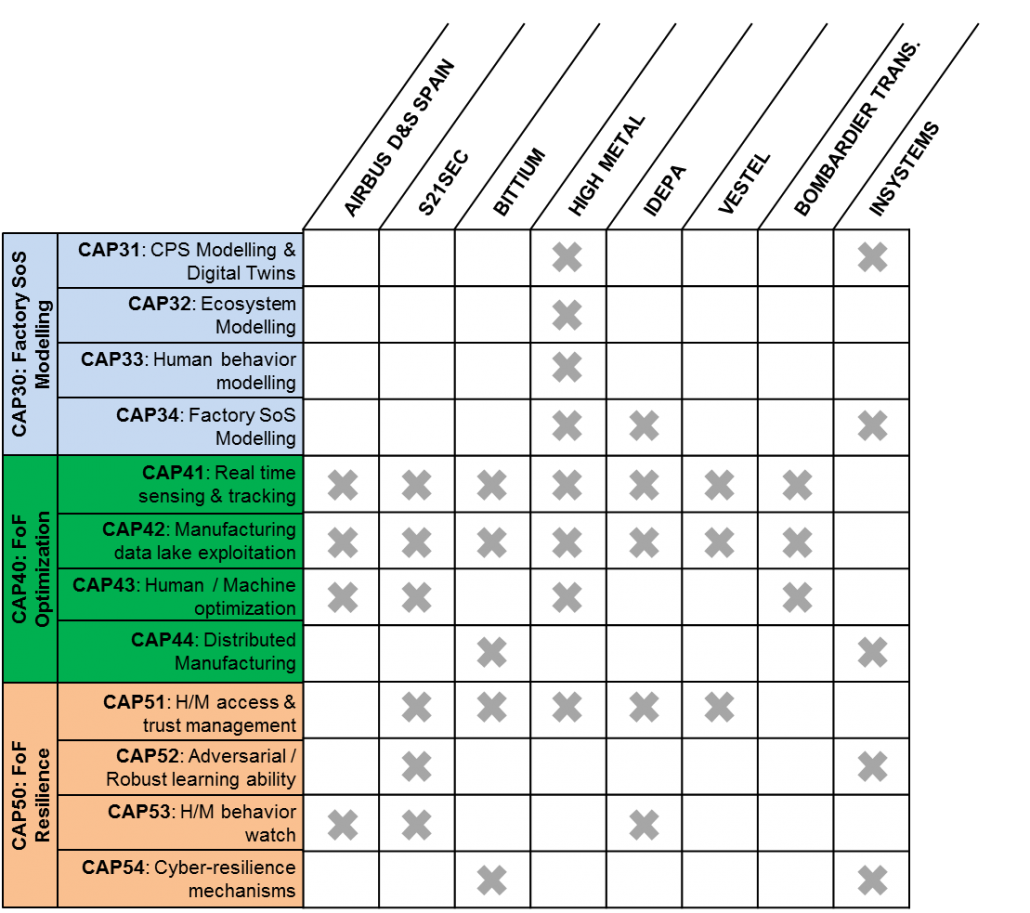

Therefore, in order to study this key problem, ten pilots have been developed from Aerospace, Automotive, Machinery and Electronic Industries around several use-cases (UC). These UC were then described and matched with Key Capabilities defined by CyberFactory#1 project proposal plan (technical value chain items):

UC1. Airbus Defense & Space (Spain):

At Airbus three sub-use cases are defined for the deployment of Industrial Internet of Things (IIoT) for flexible management and optimization of manufacturing as well assembly lines within the Aerospace Industry.

- UC1.1 Description – Roboshave (Tablada Site): Connectivity of the Roboshave station to the IIoT to improve traceability, supervision and maintenance of the processes.

- UC1.2 Description – Autoclave (CBC Site): Real-time monitoring and quality process automation across the IIoT for the process of composite parts curing and forming within Autoclaves area.

- UC1.3 Description – Gap Gun (San Pablo Sur Site): Automation of the data acquisition using a Gap Gun device (smart tool for gaps and steps measuring) with a centralized data storage and the possibility for further data analysis.

<br>

<br>

UC2. S21Sec (Spain):

This UC addresses Human/Machine collaboration in manufacturing for quality control.

- UC Description: The evolution of TRIMEK’s METROLAB solution, which focuses on quality control laboratory services towards a Zero Defect, through its integration with fully automated processes within the auxiliary automotive industry (controlling environmental variables and interconnecting the shop-floor). This means an overall enhancement of Metrolab Scenario (incorporation of several cybersecurity tools/services, including of Cobots)

<br>

<br>

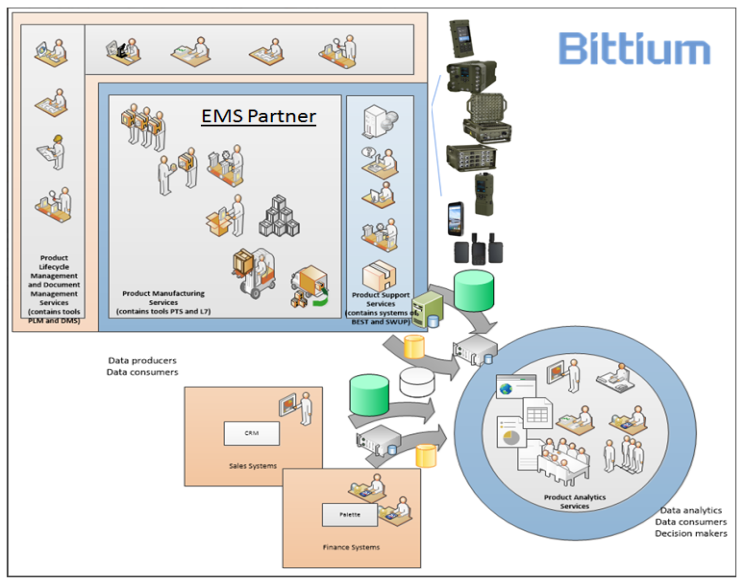

UC3. Bittium (Finland):

This UC is concerned with a cyber-secure networked supply chain and information architecture.

- UC Description: The goal is to create a consistent and secure information architecture and develop processes as well as information tools, which are able to support digital partnered manufacturing and deliveries, in order to achieve supply chain optimization.

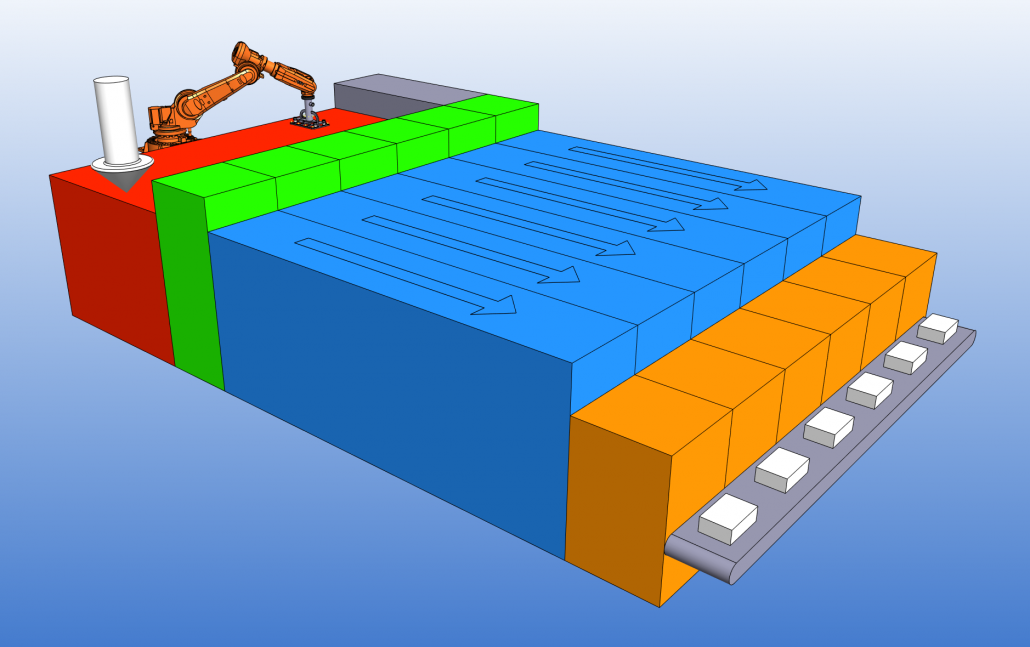

UC4. High Metal (Finland):

This UC will develop a highly automated food production line of the future (in this particular case for cheese making).

- UC Description: The High Metal UC introduces a new integrated platform-based concept for cheese manufacturing that enables: better flexibility for product quality changes, scalability for production increases, shorter installation as well as production start-up time and better efficiency and easier maintenance compared to traditional dairy production lines.

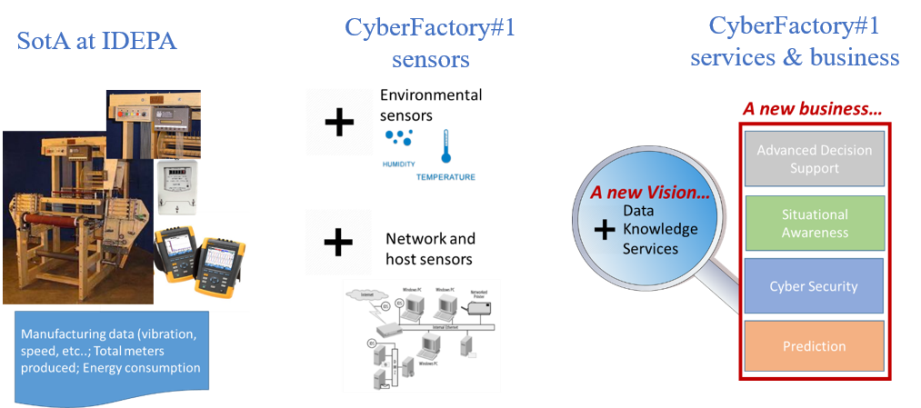

UC5. IDEPA (Portugal):

This UC will digitalize a textile production line (legacy machines) for the automotive industry.

- UC Description: The goal is to increase efficiency (and also security, safety and resilience) focusing on the development of a new generation of ERP tools, considering Security Awareness and providing Data & Knowledge as a service. This should be achieved along with IDEPA business transformation (connectivity of legacy machines).

UC6. VESTEL (Turkey):

This UC is concerned with the optimization of material handling in PCB assembly lines.

- UC Description: The objective is to pass from conventional material handling managed by operators and without data gathered from machines (no traceability) to a new situation oriented to the integration of machines in the electronic board assembly line with ERP system, warehouse and carrier robots in order to achieve optimization of the production and improving the traceability, and also considering cybersecurity aspects.

<br>

<br>

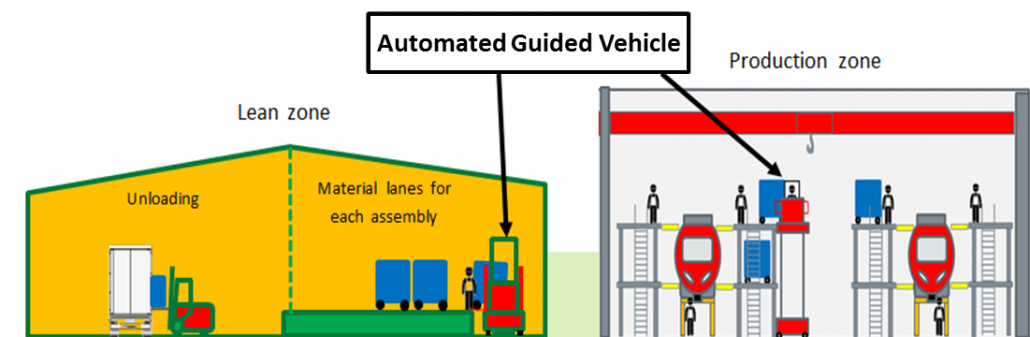

UC7. Bombardier Transporter (Germany):

This UC aims to optimize the material supply for the rail vehicle production.

- UC Description: The main objective of this UC is the optimization of material supply for railway vehicle production by building an automatic supply system from the warehouse directly to the workstations, in order to have a safe and automated provision of the material within its various physical levels (many different customer projects are carried out in parallel at the Bautzen Plant in Germany).

<br>

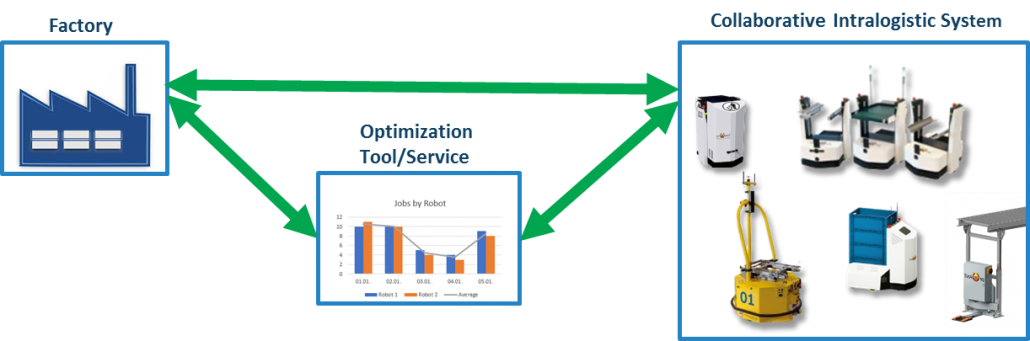

UC8. InSystems (Germany):

This UC addresses the optimization of an autonomous transport robot fleet (ProANT).

- UC Description: This UC is focused on the collection of data from normal operations of a transport robot fleet that can be used for detecting individual patterns via ML and predictive systems. This information can be also used for logistics optimization, and in a dynamical way for adaptation to continuous changes.

<br>

What is the general purpose of the use cases with the project of CyberFactory#1?

These use cases are contributing to the creation of the Factory of the Future (FoF) concept, which is the key goal of the Cyberfactory#1 project. The main objectives addressed by the different use cases developments, that may help to create this FoF concept, can be summarized as the following ones:

- Automation of E2E processes across M2B & B2M communications.

- Real time (or near real time) situational awareness and factory systems monitoring.

- Enhanced visibility and traceability of the activity within the Factory.

- Optimization and secure communications for Supply Chain (Distributed Manufacturing).

- Advanced data analytics and Machine Learning for processes improvement.

- Connectivity and integration of the Factory systems (Factory as a System of Systems).

- Communications security and global security management.

Author: José Antonio Rivero Martinez, Automation for Industrial Means, Industrial Means Dpt. – Manufacturing Engineering, Airbus Defence and Space

PS: If you are interested in more depth in one or more of the UC(s), we are happy to get you in touch with the relevant UC owner(s). Please use for all inquiries the following email address: info@cyberfactory-1.org.

https://pixabay.com/photos/writing-write-person-paperwork-828911/

https://pixabay.com/photos/writing-write-person-paperwork-828911/

https://pixabay.com/photos/writing-write-person-paperwork-828911/

https://pixabay.com/photos/writing-write-person-paperwork-828911/