One of the main objectives of CyberFactory#1 is to devise innovative ways of delivering value to the several industry sectors involved in the project through the enhancement of optimization and resilience of the production environments. The project has recently delivered a set of new business models featuring value proposition that go beyond traditional approaches, based on the intelligent product servitization (i.e. transforming product sales into services provision), the knowledge extraction from data and the focus on intellectual property (i.e. enhancing the exploitation and protection of the industrial intellectual property).

Innovative business models for eight industry sectors

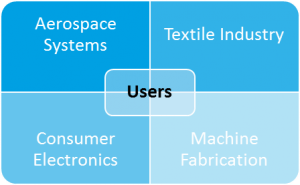

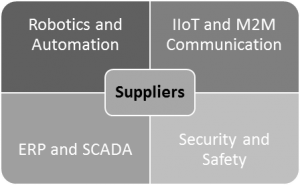

The project maps eight paradigmatic sectors and actors in the Factory of the Future (FoF) value chain, divided into two main value chain stages: users (i.e. industrial sectors which represent the end users of the new technologies and approaches developed in CyberFactory#1 – Figure 1) and suppliers (i.e. industrial sectors which provide enabling technologies to be applied in the end user activities – Figure 2).

Figure 1 – CyberFactory#1 FOF Value Chain – Users

Figure 2 – CyberFactory#1 FOF Value Chain – Suppliers

For each one of these sectors, the CyberFactory#1 developed a business model. The work, coordinated by each leading industry partner in the project, started with a rigorous analysis of the internal and external environments (including competition and market player analysis) and consolidated into a business model canvas. The business model canvas was then extended to a full-fledged business model. During this process the Cyberfactory#1 partners provided their input.

The business models were presented at the ICTurkey event in Istanbul (July 5th 2019) by the project coordinator, further raising the interest in the project of potential external partners, in particular concerning the application and exploitation of the project technologies.

Data, as a base for services

The “factory of the future” paradigm envisions a production environment in which massive amounts of data flow bottom-up from the shop floor to the highest levels of the management. This data yields a great value since it contains useful information that can be used to increase efficiency and performance as well as to enhance decision-making. However, this amount of data flow needs to be secure from unintended use and has to be trustable.

The new business models focus on the exploitation of data to extract valuable information and insights in order to make it an integral part of the transformation of products into services. Thereby they are providing increased value to industrial organizations and their customers. The exploitation of data lakes is at the core of the CyberFactory#1 business models.

Data exploitation is the key to more profitable business models based on service provision, which relies on continuous flow of value to customers instead of discrete product sale transactions (i.e. sales of distinct items). The continuous flow of value is provided through the “as-a-service” paradigm, meaning that high value services can be provided in a continuous way. Intelligence “as-a-service” can be provided through on-demand knowledge discovery from data, as well as Artificial Intelligence as-a-service (for example, provision of on-demand insight reports regarding production optimization). Management applications such as Enterprise-Resource-Planning (ERPs) and security platforms can benefit from the enhanced data value exploitation and themselves can also be provided “as-a-service” (for example, manufacturing management-as-a-service).

Lower adoption costs, greater flexibility, higher value

Servitization supports new revenue streams as it also empowers per-mile or plafond billing, flat rates or “per call” billing. This lowers the adoption costs, decreases risks both for producers and consumers and grants higher flexibility as well as scalability. This means that organizations become more capable and efficient of reacting to changes in markets.

Enhanced security also empowers service-based paradigms, as they rely on more frequent exchanges of data flows between value chain actors. Ensuring security and trust between actors makes the value chain more resilient and capable of delivering value even in the advent of internal or external cyberattacks, as well as protecting intellectual property and business-crucial information. This is especially important to enhance the protection against counterfeiting goods, to strengthen brand and to protect IP-driven competitive advantages.

Higher flexibility also opens the door for customization services (“mass customization”), allowing both industrial suppliers and users to lower production costs while being able to satisfy ever-changing customer requirements. Intelligent servitization based on data exploitation, higher flexibility, enhanced security and trust leverage the value creation in the next-generation industrial organizations, specifically in key sectors of the European industry.

Bringing benefits to European Industry

By focusing on core sectors of the European Industry, the CyberFactory#1 project also aims to build a community of manufacturing companies which can partner up with the project consortium and get involved. This is an excellent way of strengthening ties, sharing knowledge and raise awareness regarding the benefits of the several developments, including being part of enhanced value chains and considering new approaches to market and value creation.

Authors: João Mourinho, Innovation Manager, Sistrade Software Consulting & Américo Nascimento, Research/Consultant, Sistrade Software Consulting