Workshop on Cyber-Physical System Modeling: Applications for Industry 4.0 Optimization and Resilience – Call for Papers

In conjunction with ESM 2020, October 21 – October 23, 2020, Toulouse, France

This workshop focuses on the development and application of methods for modeling and simulation of CPS for the factory of the future (FoF).

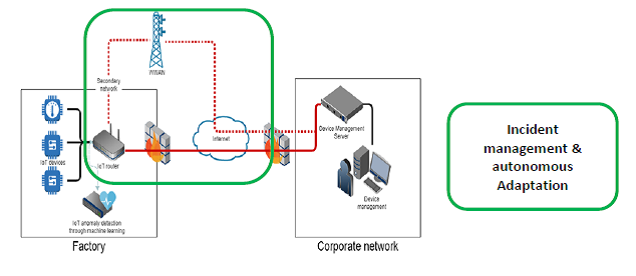

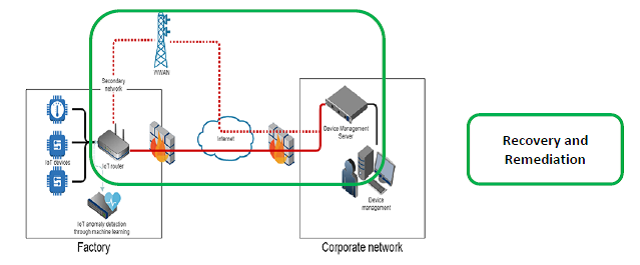

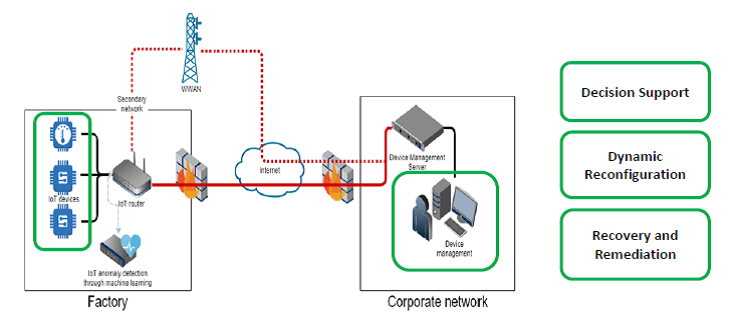

With the advent of Smart Factory, digitalization and automation processes have moved into the focus of industry. The primary goal is not the optimization of a single production plant, but of the factory as a whole by augmenting physical assets with advanced digital technologies, such as the internet of things (IoT), artificial intelligence (AI) and robots. From a modeling perspective, the individual components of the factory thus become cyber-physical systems (CPS) that communicate, analyze, and act upon information, enabling more flexible and responsive production.

The organizers invite contributions with a focus towards CPS in the FoF that describe problem statements, trends, and emerging ideas in the engineering and application of CPS in industrial production.

Topics include, but are not limited to:

- Requirements on CPS modeling for optimization and resilience of the FoF

- Architectures for the FoF

- Application of existing CPS models to manufacturing: benefits and gaps

- Usage of digital twins for optimization and resilience in the FoF

- Data lake exploitation for the FoF

- Models & Simulations for the identification of threats on safety and security in the FoF

- Tool support for modeling and simulation of the FoF

- Uncertainties and predictions in the FoF models

- Modeling of human-machine-interaction in the FoF

- Distributed manufacturing

- Cyber resilience modeling for the FoF

Paper format:

Participants may submit a 5-8 page full paper (single spaced, double column) in PDF format. Paper formatting guidelines can be found at https://www.eurosis.org/conf/esm/2020/submissions.html. All accepted papers will be published in the ESM’2020 Conference Proceedings.

Workshop format:

The workshop will be held as part of the European Simulation and Modelling Conference (ESM) 2020 to take place in Toulouse, France on October 20-23, 2020. It will feature peer-reviewed paper presentations organized according to the topics defined above. Papers not exceeding 8 pages must be submitted electronically via email (see: https://www.eurosis.org/conf/esm/2020/email-reply.html) in PDF format and must be conform to the submission guidelines (see: https://www.eurosis.org/conf/esm/2020/submissions.html).

The IEEE transaction templates can be used to get a suitable layout (see: https://journals.ieeeauthorcenter.ieee.org/create-your-ieee-journal-article/authoring-tools-and-templates/ieee-article-templates/templates-for-transactions/).

Each submission will be reviewed by at least three members of the Program Committee and will be evaluated on the basis of originality, importance of contribution, soundness, evaluation, quality of presentation and appropriate comparison to related work. The program committee as a whole will make final decisions about which submissions to accept for presentation at the conference.

Important Dates:

Paper Submission deadline: Jun 25th, 2020

Notification of acceptance/rejection: Aug 25th, 2020

Camera ready paper: Sep 30th, 2020

Workshop: Oct 21th-23th, 2020*

Organizers:

Linda Feeken (OFFIS e.V.), Eva Catarina Gomes Maia (Instituto Superior de Engenharia do Porto), Frank Oppenheimer (OFFIS e.V.), Isabel Praça (Instituto Superior de Engenharia do Porto), Ingo Stierand (OFFIS e.V.)

Contact:

Linda Feeken, linda.feeken@offis.de

Conference website: https://www.eurosis.org/conf/esm/2020

*programme of the ESM is not yet fixed, workshop will be on one of the three conference days

https://pixabay.com/photos/writing-write-person-paperwork-828911/

https://pixabay.com/photos/writing-write-person-paperwork-828911/

https://pixabay.com/photos/business-computer-mobile-smartphone-2846221/

https://pixabay.com/photos/business-computer-mobile-smartphone-2846221/